Are new energy vehicles truly environmentally friendly? What kind of contribution can the development of the new energy vehicle industry make towards achieving carbon neutrality goals? These have been persistent questions accompanying the development of the new energy vehicle industry.

Firstly, we need to understand two concepts. New energy vehicles refer to all vehicles that use energy sources other than gasoline and diesel engines. Carbon neutrality refers to achieving a balance between the total amount of carbon dioxide or greenhouse gas emissions directly or indirectly produced within a certain period of time, through energy conservation, emissions reduction, and other measures, resulting in relative “zero emissions.”

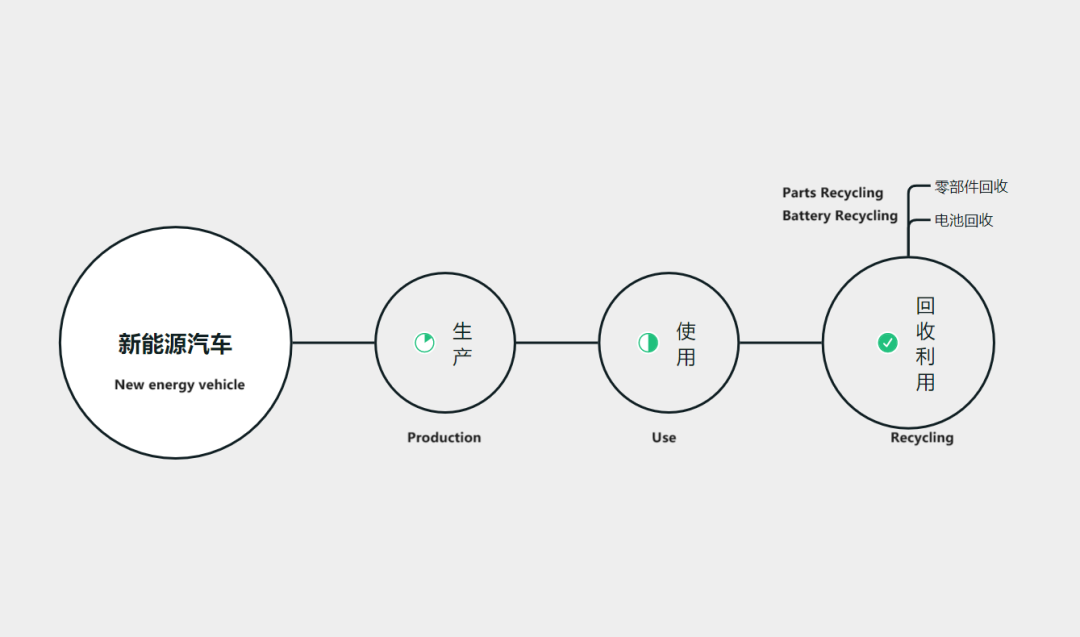

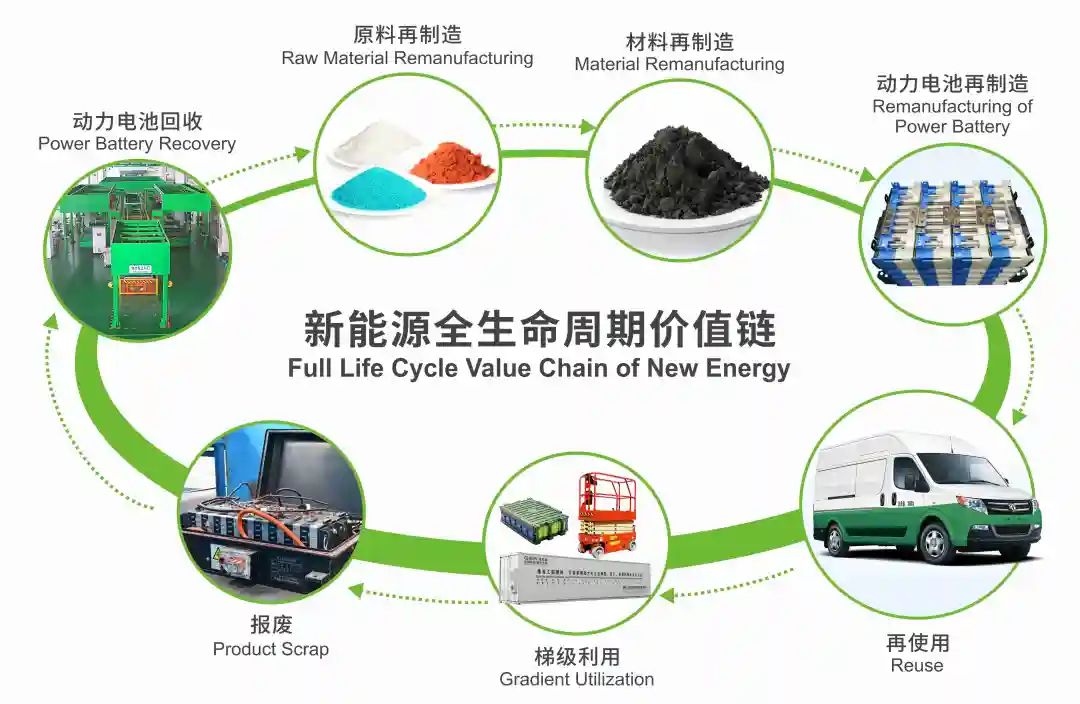

The evaluation of the carbon footprint of new energy vehicles should not be limited to factors such as tailpipe emissions and noise pollution; it should be traced back to various stages such as the collection and production of various raw materials, including the manufacturing, scrapping, and recycling processes of new energy vehicles.

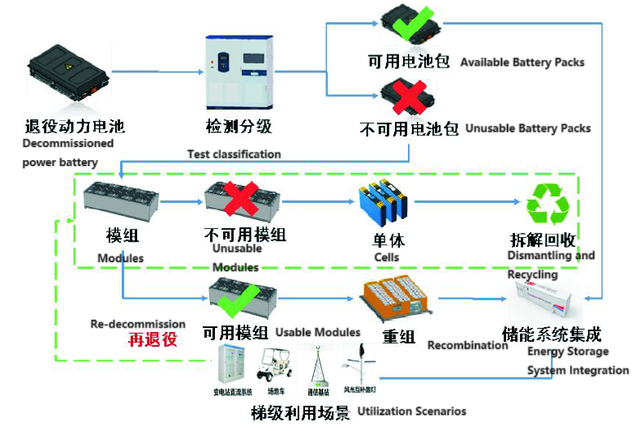

Battery recycling system:

According to current technical specifications, after the retirement of the power batteries in new energy vehicles, there is generally still 70-80% remaining capacity, which can be downgraded for energy storage, backup power, and other applications, maximizing the utilization of residual energy.

In addition, retired waste batteries are an important source of upstream materials such as lithium, cobalt, and nickel for batteries, especially in the context of rapid development of new energy vehicles where there is a high demand for battery raw materials. Currently, the country is actively promoting the construction of an efficient battery recycling system.

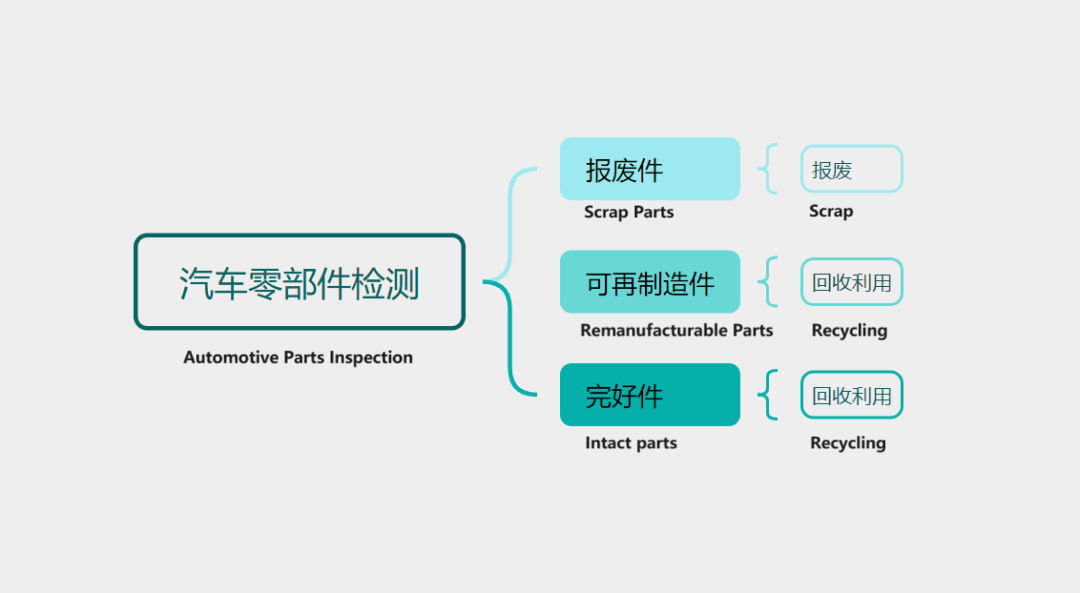

Component recycling and utilization:

Relevant data shows that at least 80% of materials from scrapped electric vehicles can be recycled and reused, and remanufacturing of components can achieve a carbon emissions reduction of over 70%. Compared to conventional vehicles, electric vehicles use more “low-carbon emission” materials.

Copper materials are widely used in pure electric vehicle drive motors, lithium-ion batteries, power transmission equipment, and power distribution systems due to their better conductivity and thermal performance. On the other hand, copper materials can be almost 100% recycled, which provides significant advantages in material recycling and component remanufacturing after parts manufacturing and vehicle scrapping, effectively reducing the carbon emissions throughout the entire lifecycle.

Driving energy industry transformation:

The widespread adoption of new energy vehicles will also promote the extensive application of green energy, driving the “peak carbon” and “carbon emissions reduction” in the energy sector. It is well-known that fossil fuels used in traditional vehicles cannot achieve zero carbon emissions, but pure electric vehicles can achieve true “carbon neutrality” by using “green electricity” from wind power, solar power, and other sources. The large-scale promotion of pure electric vehicles, the realization of “non-fossilization” of energy structures, and the promotion of renewable energy applications such as wind power and solar power will drive the “peak carbon” and “carbon neutrality” in the road transportation sector.

In conclusion, new energy vehicles, represented by pure electric vehicles, can significantly reduce carbon emissions in manufacturing, usage, and recycling and remanufacturing processes. As an automotive company in the new energy vehicle industry, YIWEI actively promotes the achievement of carbon neutrality goals in product research and development, and manufacturing. In terms of material usage, low-carbon and environmentally friendly selection criteria are implemented to promote the use of low-carbon materials. Efforts are made to improve processes and iterate technologies to enhance energy efficiency and reduce greenhouse gas emissions. Product designs also consider energy performance, and Vehicle Control Units (VCUs) with different functions are customized to meet various customer needs, resulting in energy-saving effects.

In the future, YIWEI will pursue a path of green development through green design, green manufacturing, and green operation, creating a better tomorrow for societal development.

References:

1. “The Contribution of New Energy Vehicles to Achieving China’s ‘Peak Carbon’ and ‘Carbon Neutrality’—An Analysis of the Implementation of New Energy Vehicles in Achieving ‘Peak Carbon’ and ‘Carbon Neutrality’.”

2. “Carbon Neutrality of New Energy Vehicles.”

Chengdu Yiwei New Energy Automobile Co., Ltd is a high-tech enterprise focusing on electric chassis development, vehicle control unit, electric motor, motor controller, battery pack, and intelligent network information technology of EV.

Contact us:

yanjing@1vtruck.com +(86)13921093681

duanqianyun@1vtruck.com +(86)13060058315

liyan@1vtruck.com +(86)18200390258

Post time: Dec-14-2023