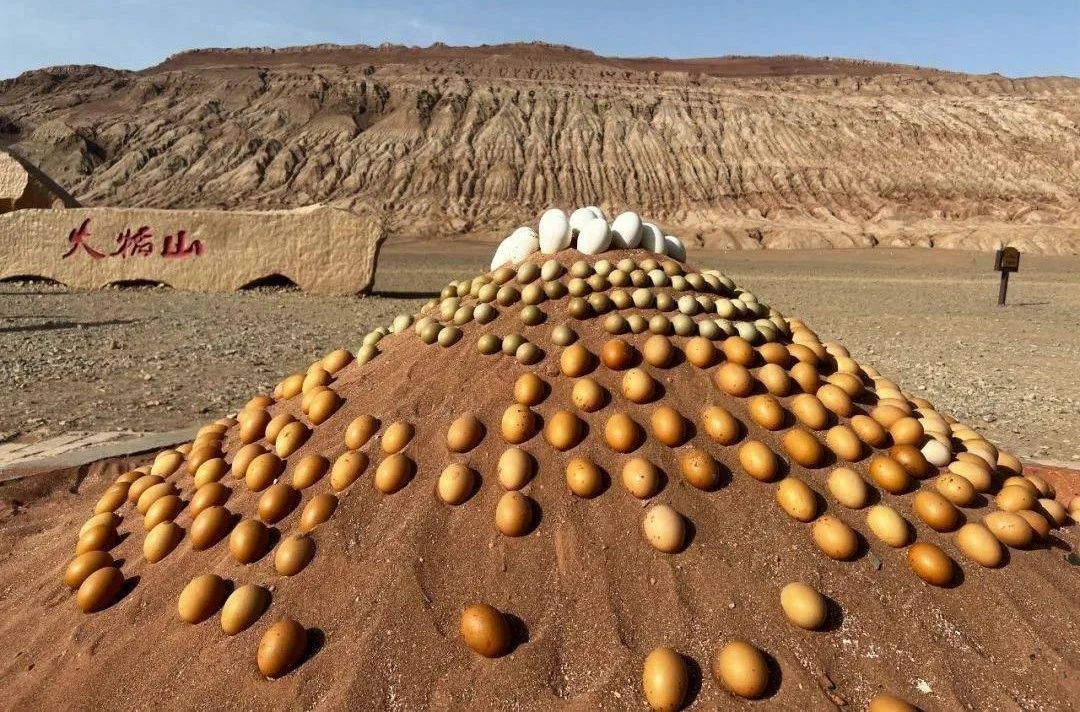

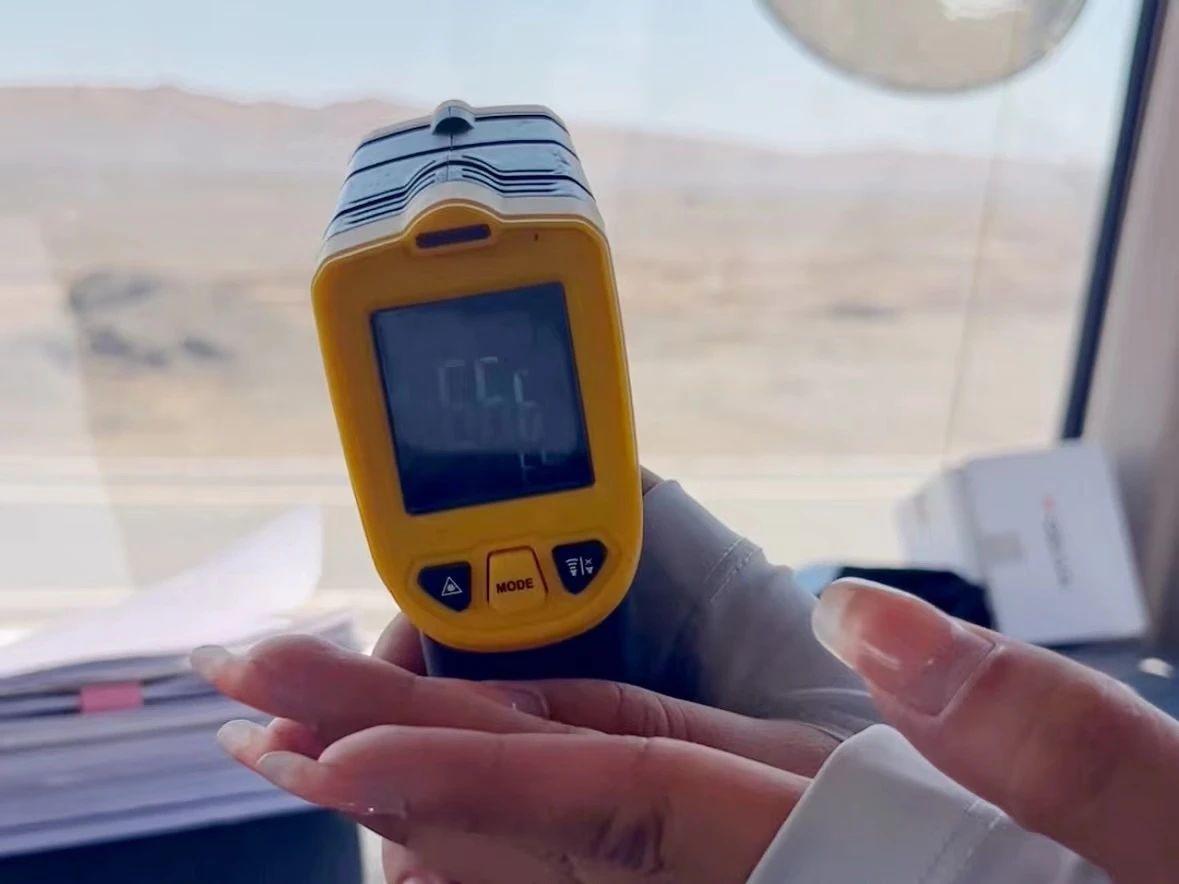

The vast expanse of the Gobi Desert and its unbearable heat provide the most extreme and authentic natural environment for automotive testing. In these conditions, key metrics such as a vehicle’s endurance in extreme temperatures, charging stability, and air conditioning performance can be thoroughly assessed. August is the hottest period of the year in Turpan, Xinjiang, where the apparent temperature for humans can reach nearly 45°C, and vehicles exposed to the sun can soar to 66.6°C. This not only subjects Yiwei’s new energy vehicles to rigorous testing but also poses a significant challenge for the engineers and drivers conducting the tests.

The intense sunlight and extremely dry air in Turpan cause the sweat of test personnel to evaporate almost instantly, and mobile phones frequently face overheating warnings. In addition to high temperatures and dryness, Turpan also frequently experiences sandstorms and other severe weather conditions. The unique climate not only tests the physical endurance of the testers but also imposes severe challenges on their work. To maintain their physical and mental condition, testers need to frequently replenish water and sugars and prepare anti-heat medications to cope with adverse reactions.

Many of the testing projects are also tests of human endurance. For example, endurance tests require the vehicle to be fully charged and driven at various speeds over several hours of alternating driving to obtain accurate results. Drivers must remain highly focused throughout the process.

During the tests, accompanying engineers must track and record data, adjust the vehicle, and replace worn-out parts. Under the 40°C heat, the skin of the testing team members becomes tanned from the sun exposure.

In brake performance testing, frequent starts and stops can lead to motion sickness, nausea, and vomiting for those in the passenger seat. Despite the harsh environment and physical challenges, the testing team remains committed to completing each test until results are obtained.

Various unexpected events also test the emergency management skills of the testing team. For instance, when testing on gravel roads, vehicle turns can cause an imbalance in friction between the tires and the gravel, easily leading to the vehicle sliding off the road and getting stuck.

The testing team quickly assesses the situation, communicates effectively, and utilizes pre-prepared emergency tools to conduct rescue operations, minimizing the impact of accidents on testing progress and vehicle safety.

The hard work of the high-temperature testing team is a microcosm of Yiwei Automotive’s pursuit of excellence and commitment to quality. The results obtained from these extreme temperature tests not only help identify potential issues in the vehicle’s design and manufacturing processes but also provide clear directions for subsequent improvements and optimizations. Additionally, they ensure the reliability and safety of vehicles under extreme climate conditions, giving customers and partners greater confidence when purchasing vehicles.

Post time: Aug-22-2024