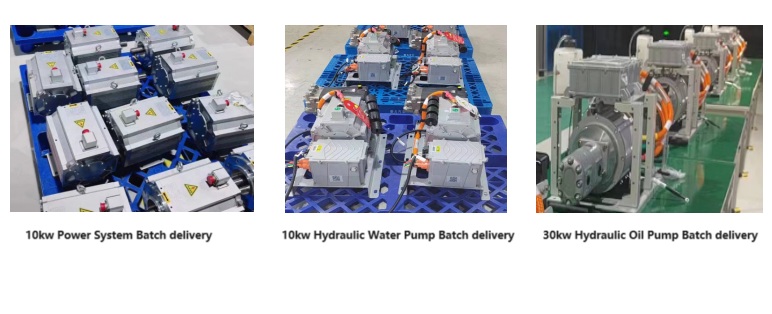

Power units installed on new energy specialized vehicles differ from those on fuel-powered vehicles. Their power is derived from an independent power system consisting of a motor, motor controller, pump, cooling system, and high/low voltage wiring harness. For different types of new energy specialized vehicles, YIWEI has customized and developed power systems with different power ratings for oil and water pumps.

As of this year, over 2,000 sets of power systems have been delivered to customers. So, what are the key points to consider during the installation and operation of the power unit?

01 Installation

– Pre-installation Preparation

Upon receiving our products, please check the materials against the packing list. If any shortages are found upon unpacking, please contact our after-sales service promptly. Inspect the appearance of the products for any damage and ensure that all fasteners are intact and securely tightened. In case of any abnormalities, please contact our after-sales service immediately.

– Mechanical Installation Requirements

Our power units are equipped with 4-8 rubber shock pads. During installation, it is essential to install these shock pads at the connection point between the power unit’s base frame and the vehicle frame. It is recommended to use self-locking nuts for securing the shock pads, and the torque applied to the nuts should not deform the rubber pads.

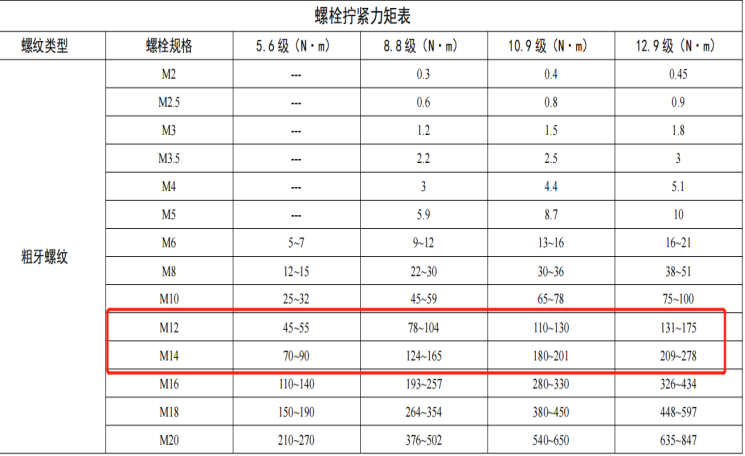

When installing the connection bolts between the power unit’s base frame and the vehicle frame, tighten them to the specified torque (except for bolts with shock pads).

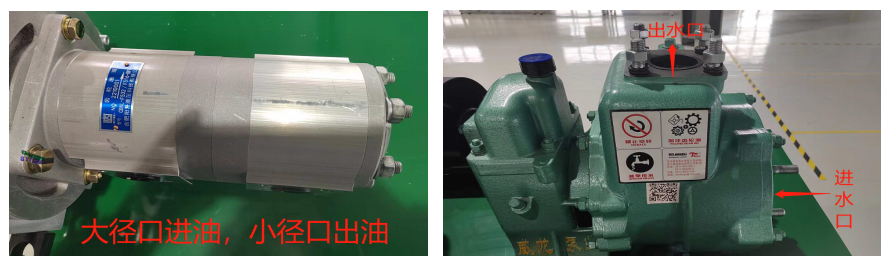

For the gear oil pump, the larger port serves as the inlet, and the smaller port serves as the outlet. For the low-pressure water pump, the X-axis is the inlet, and the Z-axis is the outlet.

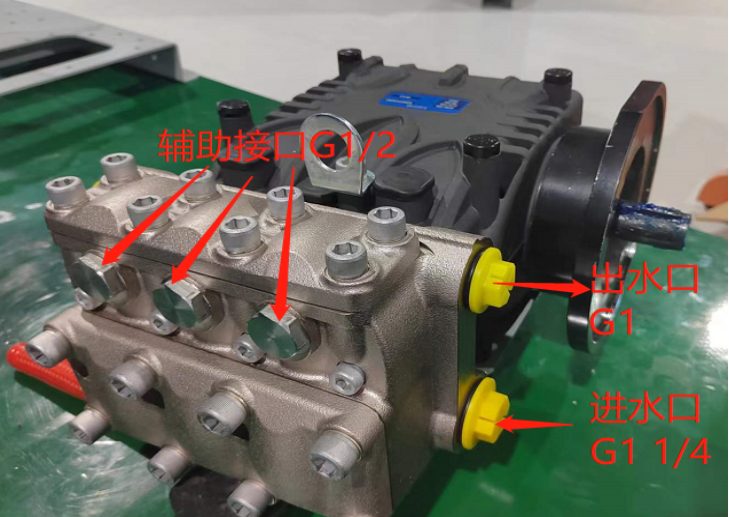

The high-pressure water pump has two inlet ports: G1 1/4”. Two water inlet pipes can be used, or one can be used while blocking the other to prevent the pump from drawing in air. It has two outlet ports: G1”. There are three auxiliary interfaces: G1/2”. The larger port is the inlet, and the smaller port is the outlet.

The red or yellow oil plug on the new pump’s crankcase oil filling port is designed for transportation convenience. In actual use, it must be replaced with the yellow oil plug included in the spare parts package.

Ensure that all connections are made with the machine stopped and the power disconnected.

– Electrical Interface Installation

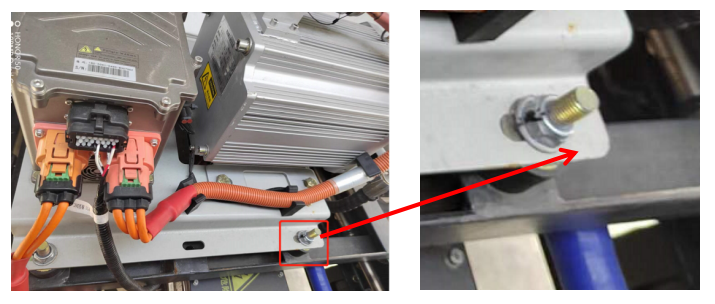

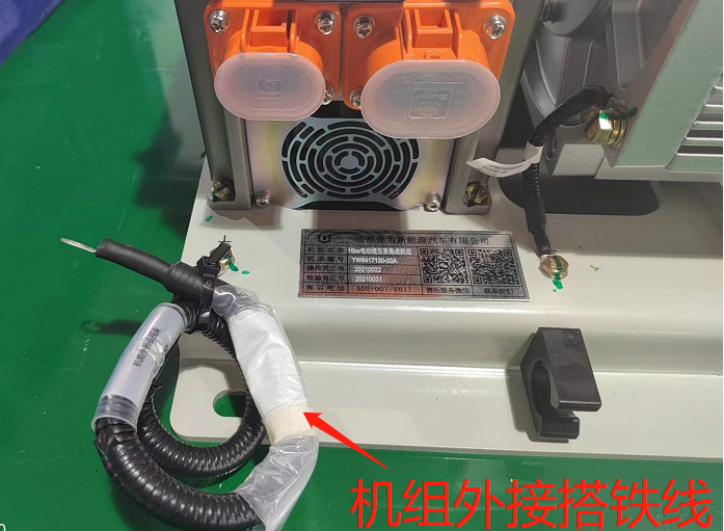

The grounding wire provided with the unit must be externally connected to the vehicle frame. During installation, use serrated washers or apply anti-rust treatment after removing paint to ensure a ground connection resistance of less than 4Ω.

When installing the high and low voltage harness connectors, follow the “listen, pull, and check” principle. Listen: The connectors should produce a “click” sound when properly installed. Pull: Pull the connectors firmly to check if they are securely attached. Check: Verify that the connectors’ locking clips are properly engaged.

When connecting the high-voltage harness, follow the positive and negative markings on the controller. After completing the connections, carefully confirm their correctness before applying high-voltage power. The torque for tightening high-voltage cable terminals is 23NM. When installing the motor controller gland, tighten it until the waterproof seal is evenly squeezed out, leaving 2-3 threads of the gland exposed.

Disconnect the battery system (MSD) for 5-10 minutes before connecting the high-voltage harness. Before connecting, use a multimeter to measure if there is any voltage at the output terminal. The operation can begin once the voltage drops below 42V.

Do not energize any exposed terminals of the low-voltage harness before completing the installation or protection. Only after all harnesses are connected can the power be applied. When installing the harness, follow the rule of securing it every 30cm. The high and low voltage harnesses should be fixed separately and must not be secured together with high-pressure oil or water pipes. Use protective rubber strips when passing the harness over sharp metal edges. Unused plug holes must be sealed with sealing plugs, and reserved connector holes must be plugged with matching plugs. Unauthorized rewiring is strictly prohibited without the consent of our technical personnel.

02 Operation

During the initial use of the cooling system, there may be some air present. The electronic water pump may experience a free-running protection condition. During operation, regularly check if the electronic water pump stops. If it does, restart the pump after restoring power.

Avoid prolonged free-running of the high and low-pressure water pumps and oil pump. The free-running time should be ≤30 seconds. During the unit’s operation, pay attention to its operating sound, vibration, and rotation direction. If any abnormalities are detected, immediately stop the motor and perform an inspection. Only after troubleshooting is completed can the unit be used.

Before starting the oil pump unit, open the oil circuit valve, and before starting the water pump unit, open the water circuit valve.

Chengdu Yiwei New Energy Automobile Co., Ltd is a high-tech enterprise focusing on electric chassis development, vehicle control unit, electric motor, motor controller, battery pack, and intelligent network information technology of EV.

Contact us:

yanjing@1vtruck.com +(86)13921093681

duanqianyun@1vtruck.com +(86)13060058315

liyan@1vtruck.com +(86)18200390258

Post time: Jan-15-2024