01 What is a permanent magnet synchronous motor:

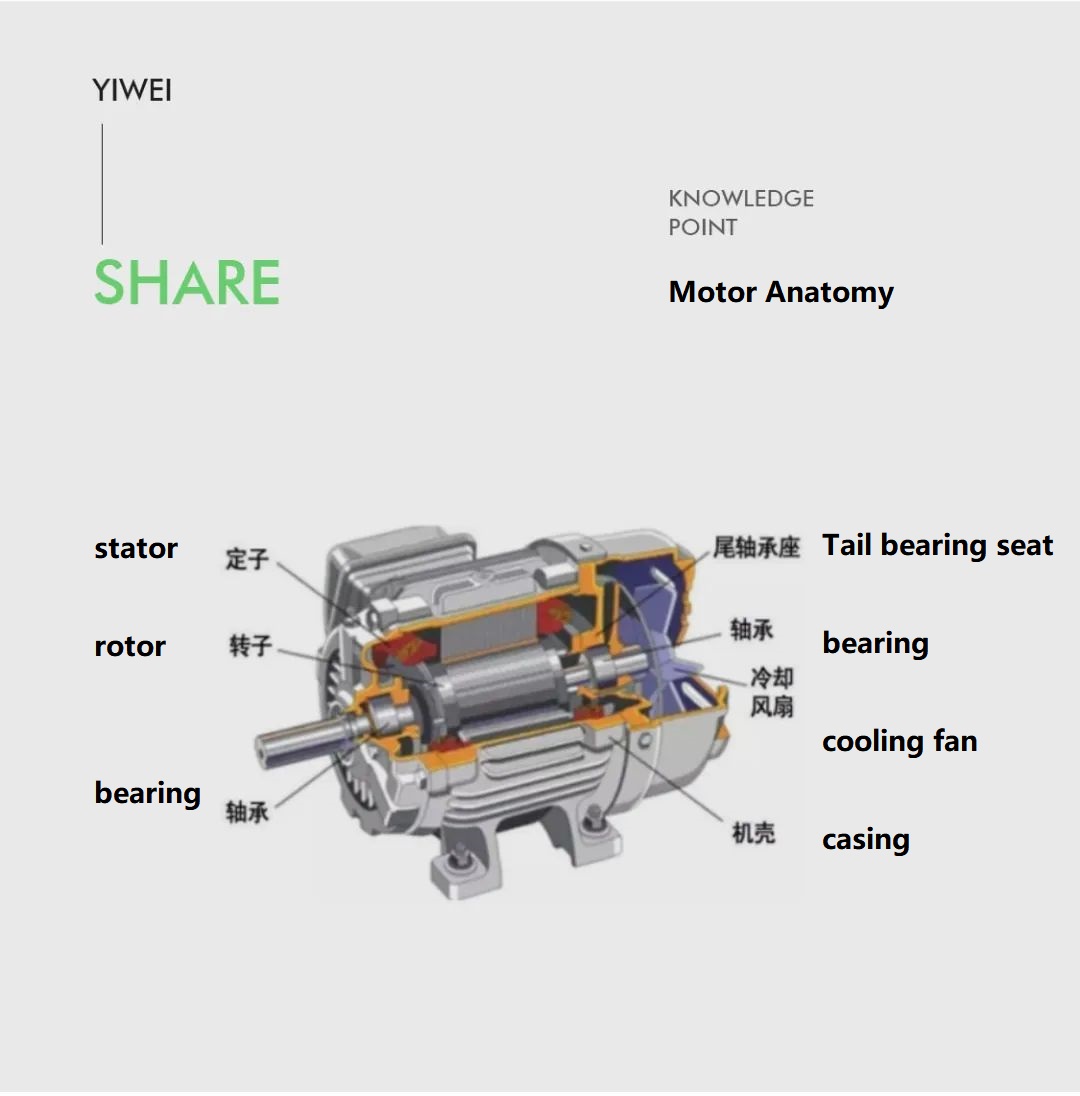

Permanent magnet synchronous motor mainly consists of rotor, end cover and stator, where permanent magnet means that the motor rotor carries high quality permanent magnets, synchronous means that the rotor rotating speed and stator generated by the rotating “magnet” rotating speed is equal.

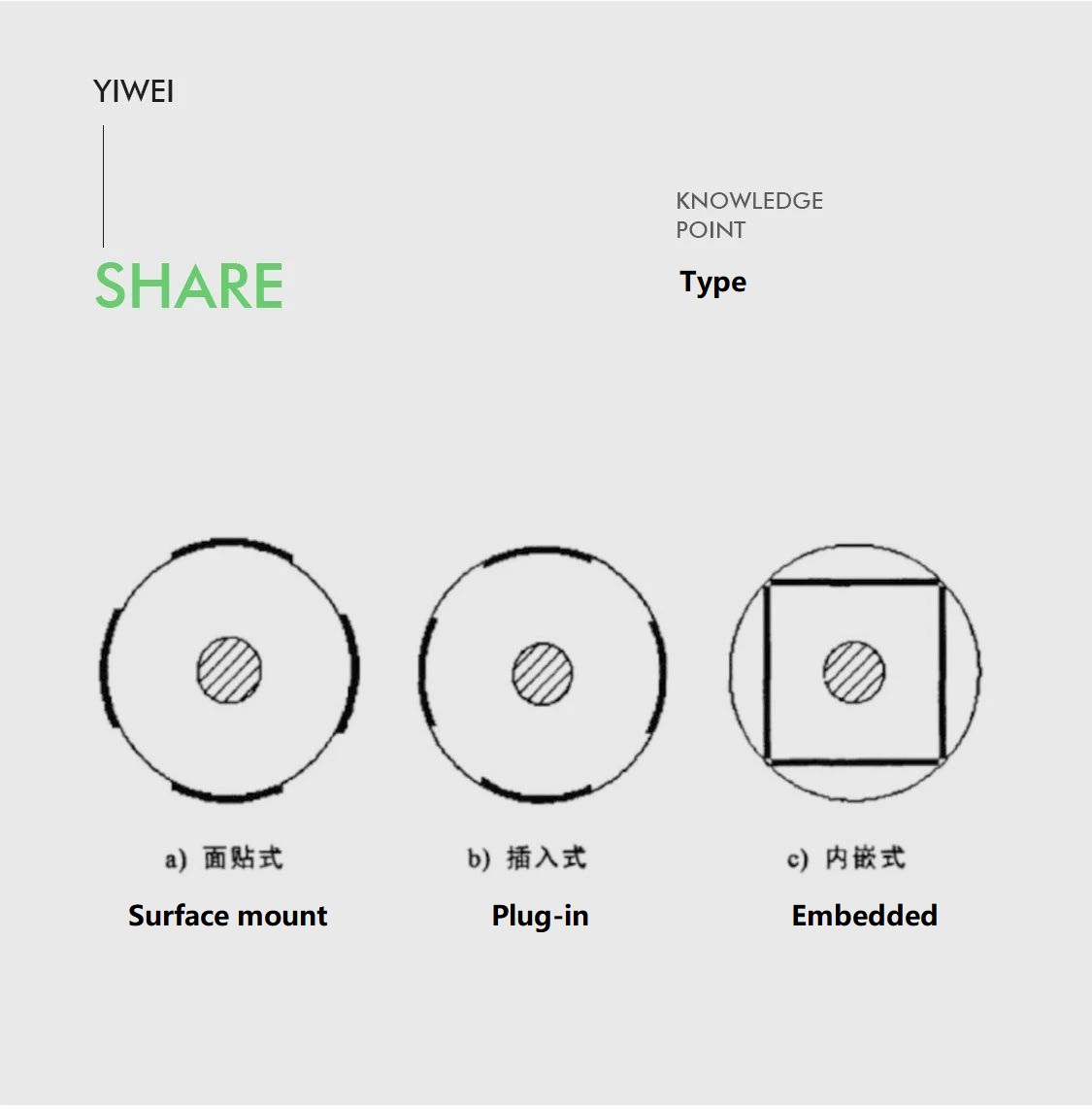

The biggest difference with other motors is that the rotor is equipped with permanent magnets constitute a unique structure, and the position of the permanent magnets do not make it possible to produce different types, mainly divided into surface-mounted, inserted and embedded type.

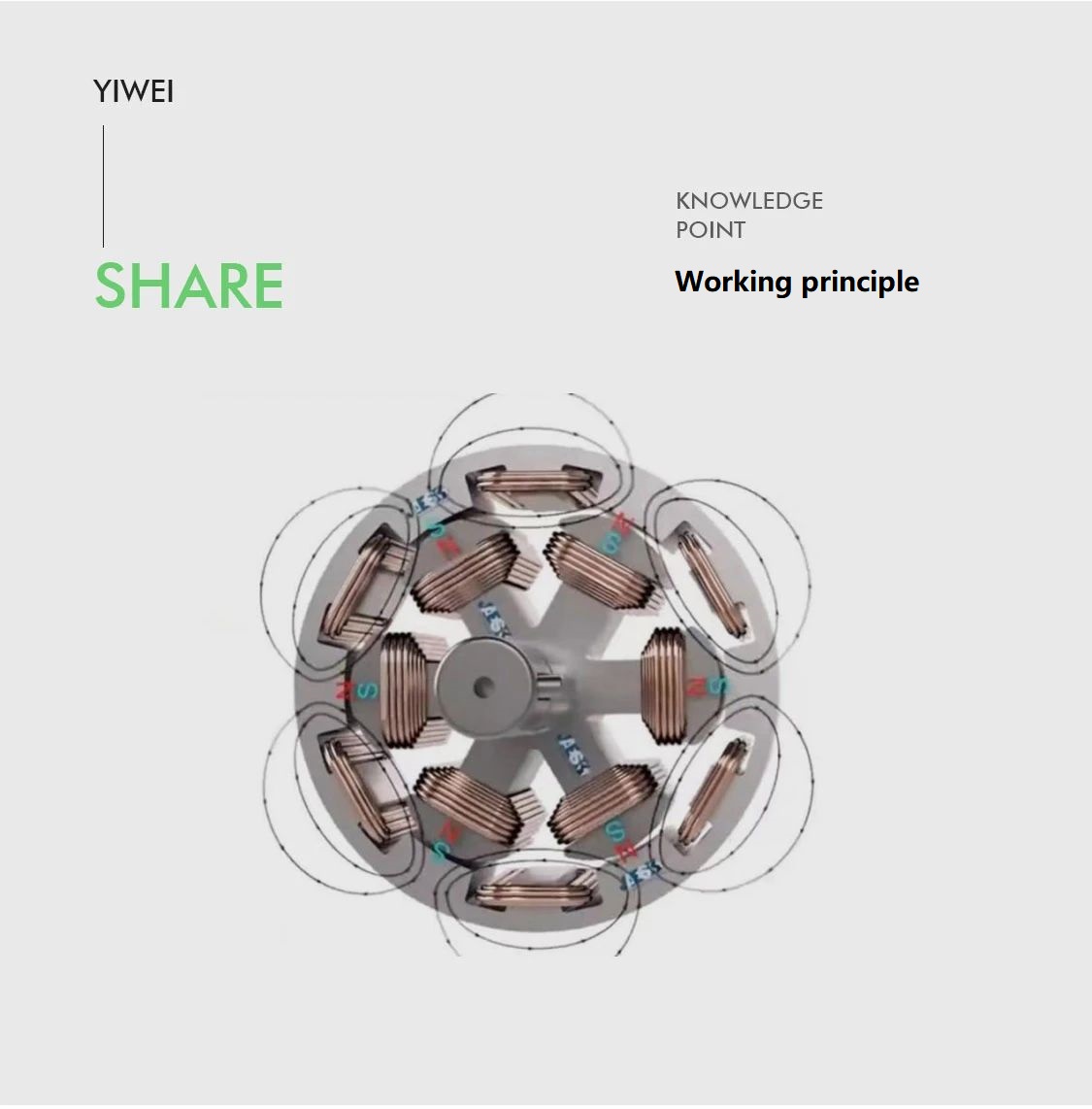

02 permanent magnet synchronous motor working principle.

Through the familiar UVW three-phase line to obtain alternating current to the stator inside the special winding, because of the alternating current and the distribution structure of the winding will produce rotating magnetic field. According to the principle of magnetic poles repel in the same direction and attract in the opposite direction, the rotating magnetic field will drag the rotor carrying permanent magnets in the middle until the rotating speed of the rotor reaches the speed of the rotating magnetic field, and the motor enters into a stable working state.

03 Advantages of permanent magnet synchronous motor:

The permanent magnet synchronous motor has the following advantages according to the uniqueness of its structure:

Good cooling system:

Permanent magnet synchronous motor generates little heat, so the motor cooling system is simple in structure, small in size and low in noise.

Good structure:

The system adopts fully closed structure, no transmission gear wear, no transmission gear noise, lubricant-free and maintenance-free.

High efficiency:

Permanent magnet synchronous motor allows a large overload current, reliability is significantly improved; the whole transmission system is light in weight, and the unsprung weight is also lighter than that of the traditional wheel and axle drive, and the power per unit of weight is large; because permanent magnet synchronous motor does not have a gear box, it can make the vehicle power performance greatly improved; there is no copper loss and iron loss in the rotor, and there is no friction loss in the collector ring and brushes, and the operation efficiency is high.

Light weight:

Permanent magnet synchronous motor rotor adopts permanent magnet material pole, especially the use of rare earth metal permanent magnets (such as neodymium iron boron, etc.), its magnetic energy product is high, can get a high air gap magnetic flux density, so in the capacity of the same, the motor’s volume is small, light weight.

Reliable operation:

Small rotational inertia, large permissible pulse torque, high acceleration can be obtained, good dynamic performance, compact structure, reliable operation.

Can be used as a generator:

Because the characteristics of permanent magnet synchronous motor can be used as a high-efficiency generator, so it can also meet the new energy vehicles with energy recovery function.

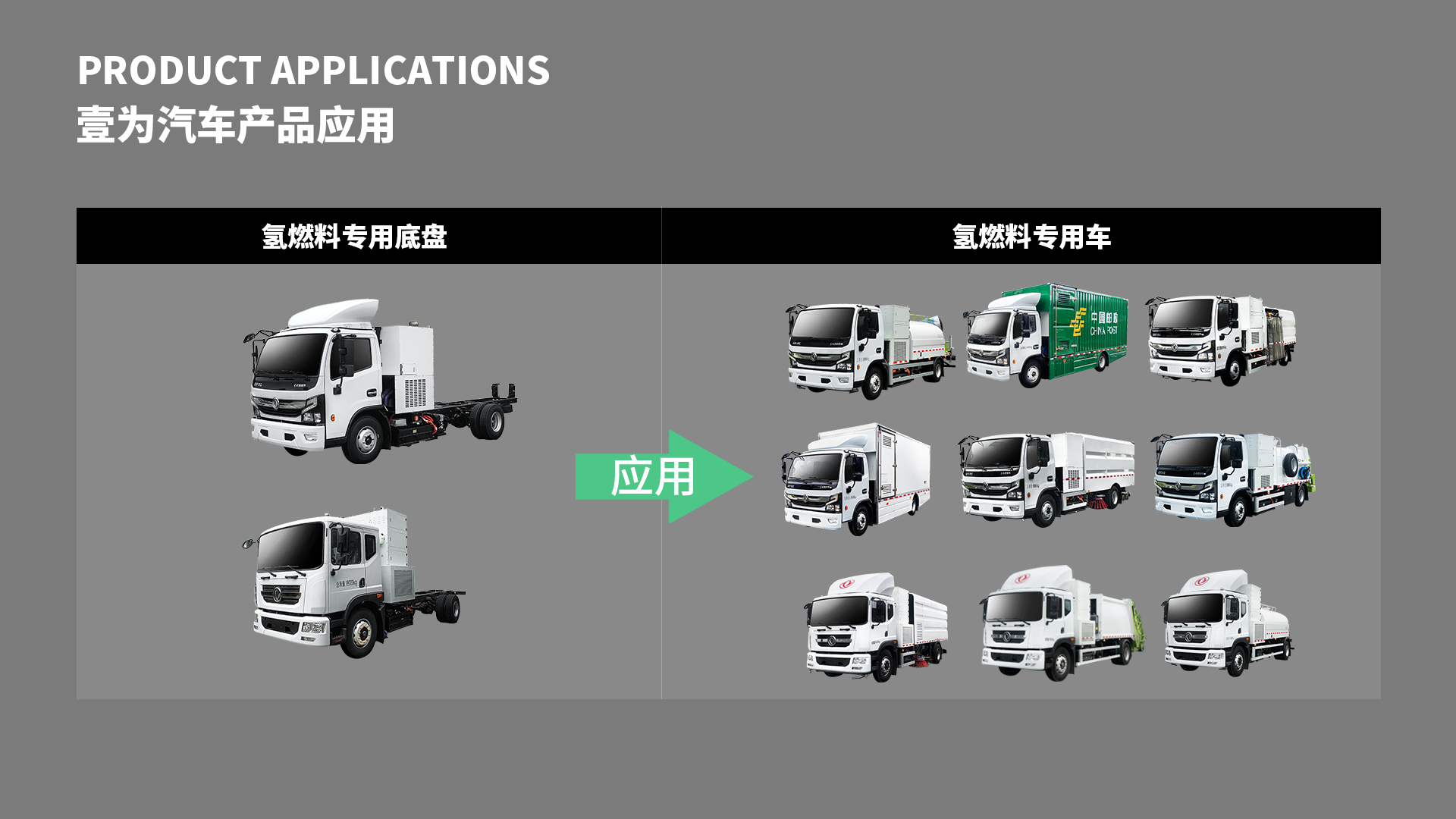

04 permanent magnet synchronous motor applications:

In the one for the car 2.7 tons, 4.5 tons, 9 tons, 12 tons, 18 tons, 25 tons and 31 tons of the body are equipped with safe and reliable permanent magnet synchronous motor, for the safe and reliable operation of the vehicle to provide a favorable guarantee.

Contact us:

yanjing@1vtruck.com +(86)13921093681

duanqianyun@1vtruck.com +(86)13060058315

liyan@1vtruck.com +(86)18200390258

Post time: Sep-06-2023