The chassis, as the supporting structure and core skeleton of a vehicle, bears the entire weight of the vehicle and various dynamic loads during driving. To ensure the safety and stability of the vehicle, the chassis must have sufficient strength and rigidity. However, we often see many holes in the chassis. Does this affect the strength of the chassis?

In the manufacturing process of Yiwei Automobile, the chassis drilling process is particularly important. This process is not carried out arbitrarily but is carefully designed based on in-depth engineering principles and practical needs. The purpose of drilling is to optimize the stress distribution of the chassis, improve structural efficiency, and achieve lightweight goals, thereby meeting the pursuit of high performance and low energy consumption of modern special vehicles. In addition, the holes in the chassis also provide necessary connection points and passages for various installation components, wiring harnesses, and pipelines, ensuring the normal operation of vehicle facilities.

Significant weight reduction: Chassis drilling can effectively reduce its own weight, thereby reducing the overall vehicle weight. In the modern automobile manufacturing industry, lightweight design is an important trend, which can improve the range and overall performance of special vehicles. At the same time, Yiwei Automobile has successfully achieved the goal of lightweight design in the overall layout of the chassis. Several independently developed chassis have reached the industry-leading level under the same battery capacity configuration.

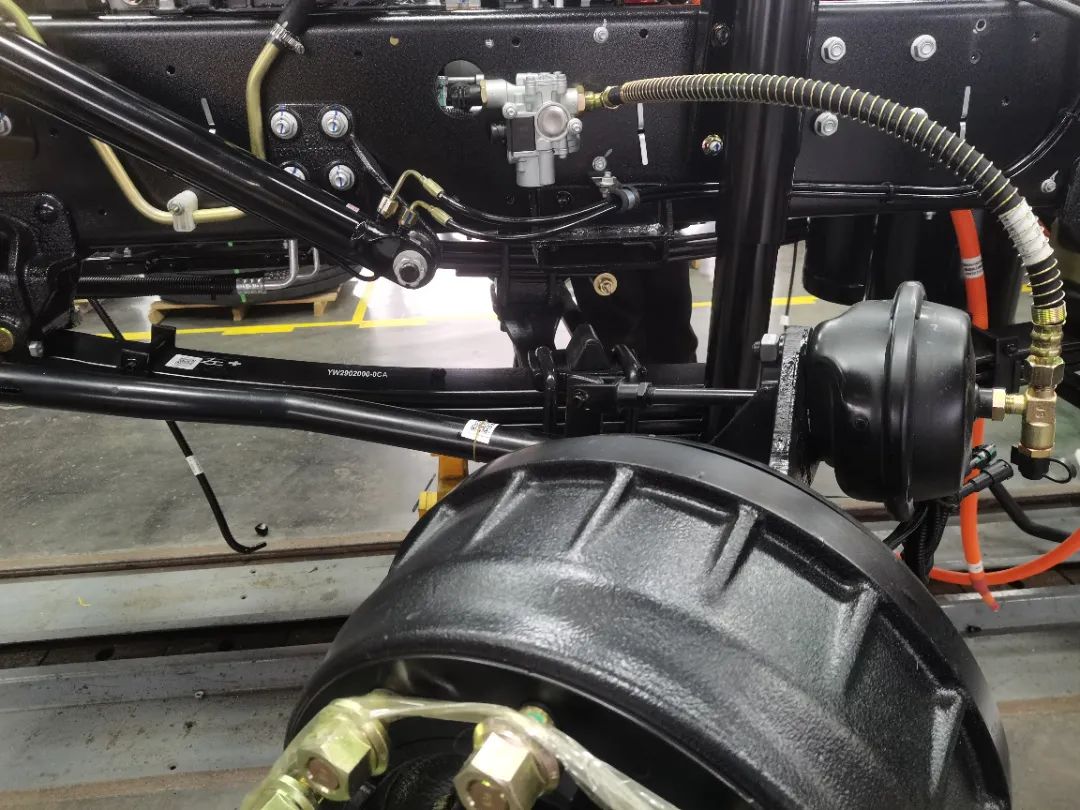

Installation components: The mounting holes on the chassis are mainly used to fix various installation components on the chassis through bolts or rivets, such as motor gearboxes and air pumps. These hole positions are set according to the location and requirements of the installation components to ensure that the vehicle components can be firmly connected.

Compact layout: Some holes serve as passages for wires and pipes, making the internal layout of the chassis more compact and orderly. This not only improves space utilization but also facilitates later maintenance and repairs.

Efficient processing and assembly: The holes in the chassis facilitate the processing and assembly process, improving production efficiency. In the production process, hole shapes and sizes can be formed on the chassis beams through drilling and punching processes, ensuring precise assembly between parts.

Stress dispersion: Drilling holes in areas with low stress helps to disperse and release internal stress in the chassis, avoiding stress concentration. This not only improves the rigidity and fatigue strength of the chassis but also extends its service life.

Heat dissipation and ventilation: Holes also help with heat dissipation and ventilation, improving the vehicle’s heat dissipation effect and helping to eliminate moisture and odors inside the vehicle.

In summary, the core purpose of the chassis drilling process is to adapt to the growing demands for lightweight design, rigidity enhancement, and efficient component assembly in modern automobile manufacturing. In the R&D and design stage, Yiwei Automobile strictly follows structural mechanics principles and industry design standards, carefully balancing the relationship between lightweight design and vehicle safety performance and service life, ensuring that safety and durability are not sacrificed while pursuing lightweight design, and reducing customer operating costs.

Post time: Jan-06-2025