High-temperature testing is an essential part of the R&D and quality control process for new energy vehicles. As extreme high-temperature weather becomes increasingly frequent, the reliability and stability of new energy sanitation vehicles directly impact the efficient operation of urban sanitation services and the ongoing improvement of the environment. To address this, Yiwei Automobile conducted high-temperature tests in Turpan, Xinjiang, this summer to thoroughly verify the stability and reliability of their vehicles, including high-temperature charging, air conditioning cooling, range under high temperatures, and braking performance.

Through a series of rigorous tests, Yiwei Automobile demonstrated exceptional product performance, successfully withstanding the harsh conditions. Notably, this is the second consecutive year Yiwei has conducted summer high-temperature tests in Turpan, making it the first specialized vehicle company in the country to consistently perform high-temperature tests on pure electric sanitation vehicles.

Compared to last year, this year’s testing featured a wider range of vehicle models and a more comprehensive set of projects, including self-developed 18t street sweepers, 18t water trucks, 12t multifunctional dust suppression vehicles, 10t kitchen waste trucks, and 4.5t compression garbage trucks, totaling eight major categories and over 300 tests, with each vehicle covering more than 10,000 km.

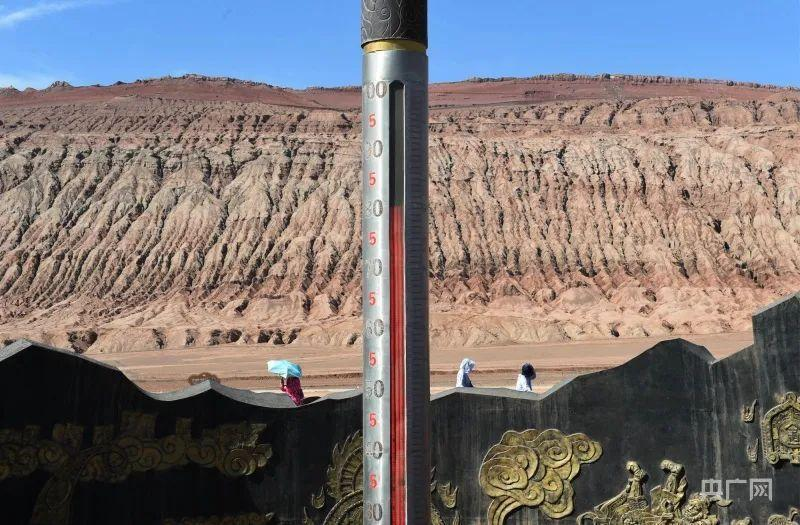

This summer, temperatures in Turpan frequently exceeded 40°C, with ground temperatures approaching 70°C. In the famous Flaming Mountains, surface temperatures reached as high as 81°C. For pure electric sanitation vehicles, driving range is a critical factor for efficient operations and expanding operational scope. Under 43°C conditions, Yiwei tested five pure electric sanitation vehicles, each exceeding 10,000 km in mileage while simulating continuous air conditioning and full-load driving conditions. For example, the 18t street sweeper maintained a speed of 40 km/h under high temperature and full load, achieving a range of 378 km. Additionally, Yiwei can extend range or operational time by increasing battery capacity based on user needs.

Charging safety and efficiency are also key concerns for users of new energy sanitation vehicles in high-temperature environments. Yiwei repeatedly verified that whether the vehicle was stationary in the heat or had been driven for long periods, it could charge successfully each time. For instance, the 4.5t compression truck required only 40 minutes to charge from a SOC of 20% to 80%, and 60 minutes to charge from 20% to 100%.

Yiwei’s integrated thermal management system performed exceptionally well during high-temperature testing, maintaining efficient operation and ensuring that the battery pack and charging system stayed within optimal temperature ranges. This not only enhanced charging speed but also effectively protected the battery, extending its lifespan.

To thoroughly assess Yiwei’s air conditioning cooling capabilities under high temperatures, five vehicles were exposed to direct sunlight for four hours before evaluating their air conditioning settings, airflow, and cooling performance. All vehicles performed normally and were able to cool quickly. For example, the 18t water truck’s internal temperature rose to 60°C after exposure, but after running the air conditioning for 10 minutes, the temperature dropped to 25°C.

In addition to air conditioning, the vehicles’ sealing effectively blocked external heat and noise. Measurements showed that even at maximum air conditioning airflow, interior noise levels remained around 60 decibels, providing a cool and comfortable driving environment. During road operations, noise levels were kept at 65 decibels, well below the national standard of 84 decibels, ensuring that sanitation operations at night do not disturb residents.

Safety is a core value that Yiwei consistently upholds. During this high-temperature testing, the vehicles underwent over 10,000 km of driving verification, operational testing, and both (empty/load) braking and performance tests. Throughout testing, Yiwei’s sanitation operational functions, tires, suspension, and braking systems maintained high stability, with no performance degradation observed.

In the braking tests, the 18t model under full load was tested at a speed of 60 km/h, achieving a stopping distance of 26.88 meters (in 3 seconds) for the water truck and 23.98 meters (in 2.8 seconds) for the street sweeper, demonstrating rapid and short-distance braking capabilities, which are crucial for safety in complex urban road conditions.

High-temperature testing is one of the important means to promote technological advancement in new energy sanitation vehicles. These tests drive product innovation and upgrades, and the results can provide crucial references for setting industry standards for new energy sanitation vehicles. As the first specialized vehicle company in the country to conduct “three high tests” on pure electric sanitation vehicles, Yiwei is committed not only to providing customers with more stable and reliable products but also to advancing the entire industry toward greater safety, efficiency, and intelligence.

Post time: Sep-30-2024