Standard Maintenance - Water Filter and Central Control Valve Cleaning and Maintenance Guidelines

With the gradual increase in temperature, the water consumption of sanitation vehicles multiplies. Some customers encounter issues during vehicle usage, such as improper cleaning of the water filter and variations in water quality, which can lead to water filter clogging, water pump damage, central control valve sticking, and nozzle blockage.

To address these issues, we would like to share some practical cleaning and troubleshooting methods with you.

Image 1: Water filter clogging due to uncleared impurities

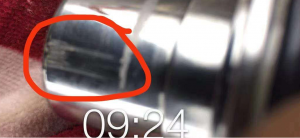

Image 2: Sticking of central control water valve and damage to valve core

clean water filter steps

01

The lower portion of the water filter is equipped with a drain valve. Before each shift, it is necessary to open the drain valve to flush out any impurities from the filter element.

02

Every 2-3 working days (or more frequently if water quality is poor), the water filter housing should be removed for cleaning of the filter element.

Note: Use clean pressurized tap water for flushing the inner surface of the filter element. Flushing from the inside to the outside helps prevent impurities from forcefully entering the filter element, thereby prolonging its lifespan.

03

If any damage is observed on the filter element or the housing's "O"-ring seal, immediate replacement is necessary. Ensure a proper seal by tightening the sealing surface of the filter element and the "O"-ring seal on the housing. A non-sealing water filter or a clogged filter element without water can result in water pump cavitation, leading to pump damage and other issues.

04

The filter element should be replaced regularly, ideally every 6 months!

Note: For customers without access to clean tap water on-site, it is recommended to have an additional filter element. This allows for separate removal and cleaning of the filter elements, preventing contamination. Both filter elements can be alternated and cleaned.

When the water quality used for washing or cleaning vehicles is poor or when the water filter is not cleaned in a timely manner, it is prone to causing sticking of the pneumatic control valve core. The symptom of this failure is continuous water flow from the spray lance even after the operation is completed.

Troubleshooting Method 1

01

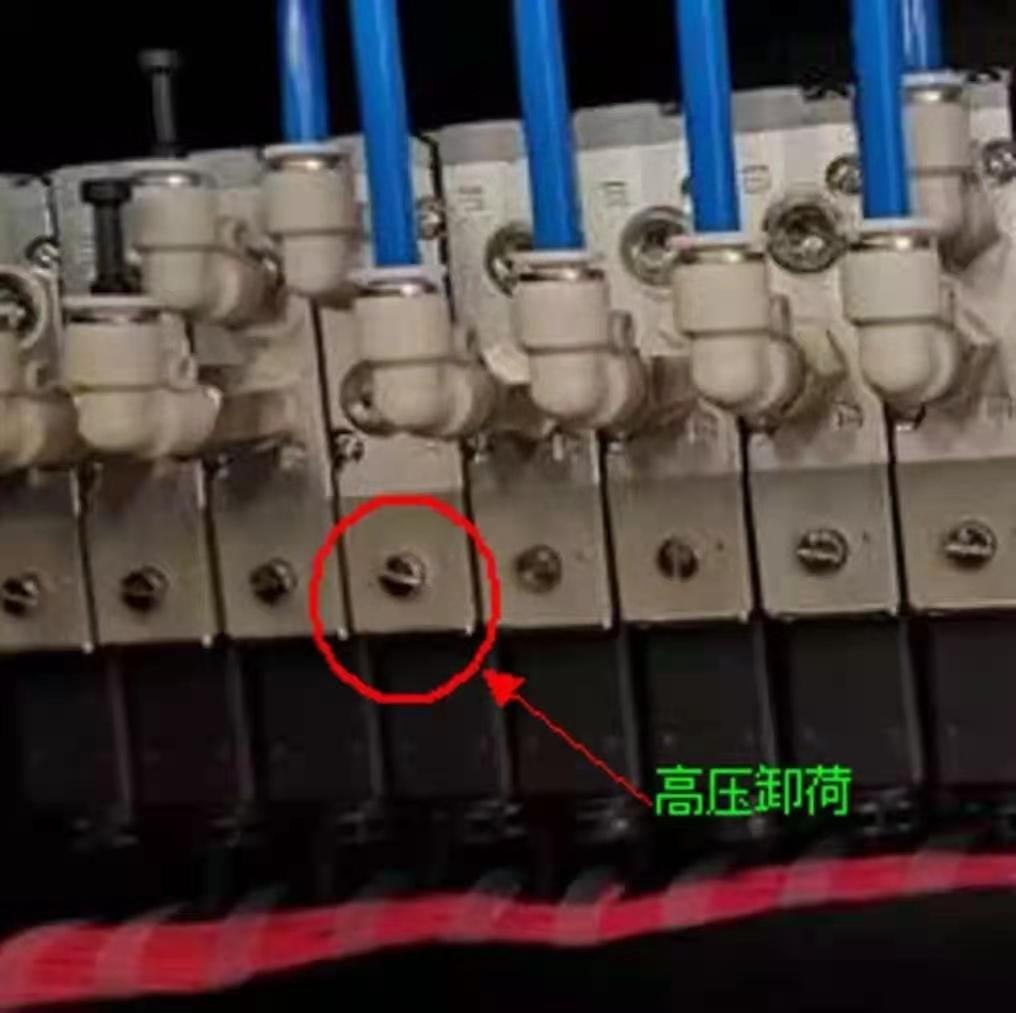

While the high-pressure water pump is running, open the pneumatic control box and quickly press the button of the unloading solenoid valve (as shown in the figure below; different vehicle models may have variations). This action will close the valve core due to the impact of high-pressure water flow.

02

Alternatively, you can also press the corresponding solenoid valve of the faulty central control water valve. If you can hear a distinct and robust opening and closing sound of the valve, it indicates that normal operation has been restored.

By following these steps, the probability of needing to clean or replace the central control water valve can be significantly reduced. If the issue persists, please refer to "Troubleshooting Method 2" below.

Troubleshooting Method 2

01

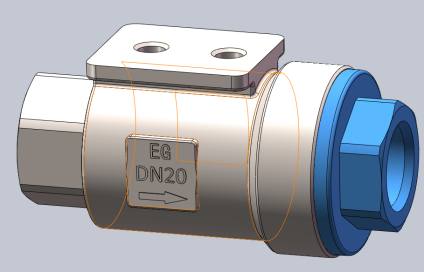

Using a size 27 wrench, detach the hose at the back of the valve and remove the valve cover (blue in the figure below).

02

The following five components will be exposed upon separation: Component number 2 can be cleaned using dishwashing detergent or soapy water.

During the vehicle usage, proper and standardized maintenance operations can effectively improve the vehicle's lifespan and extend its operational time. YIWEI Automotive would like to remind all drivers to perform regular vehicle inspections and timely maintenance. If you encounter any vehicle issues, please contact our dedicated service personnel for assistance.

YIWEI Automotive is committed to providing you with high-quality electric vehicle conversion parts, sanitation vehicles, and comprehensive solutions, sharing a greener Earth with you.

Contact us:

yanjing@1vtruck.com +(86)13921093681

duanqianyun@1vtruck.com +(86)13060058315

liyan@1vtruck.com +(86)18200390258

Post time: Sep-05-2023