The production process of the cable also requires quality control at each level:

First, size control. The size of the cable depends on the layout of the cable material specifications determined at the beginning of the design on a 1:1 digital model to obtain the corresponding size. Therefore, in the production process, the size needs to be cut strictly according to the design size using a pneumatic cutting machine to avoid manual cutting leading to inaccurate size.

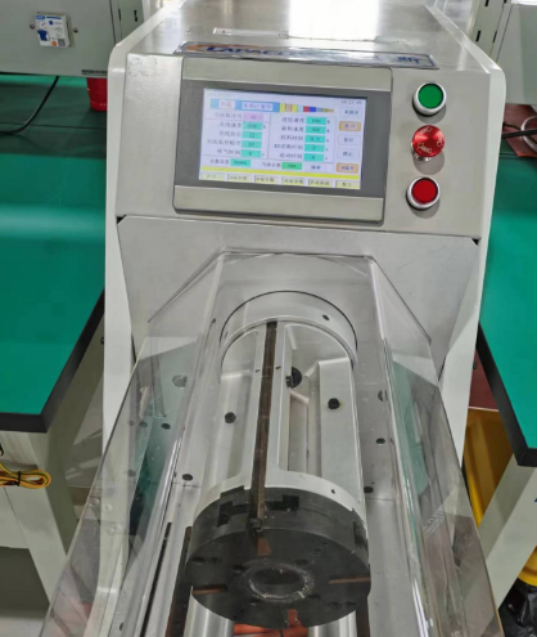

Second, cable end processing. The processing of the high-voltage cable end requires differentiation based on the wire diameter matched during the design and the material selection. For example, the processing of a single-core shielded cable requires the use of a fully automatic wire stripping machine to accurately control the end size to ensure that there no insulation problems after production.

Third, high-voltage wire terminal crimping. The selection of different specifications of high-voltage wires corresponds to different terminal crimping methods. We adjust different parameters on the CNC hydraulic terminal machine according to different wire specifications to crimp the wire terminals. When crimping, the terminals need to be crimped into a hexagonal shape to ensure safety.

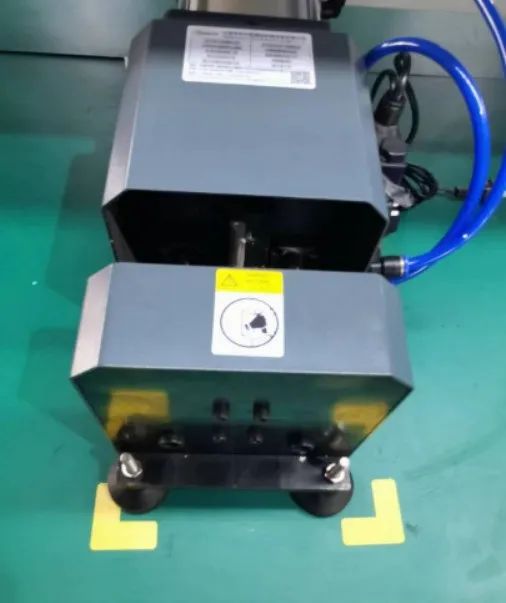

Fourth, tension testing after cable selection. After crimping the wire terminals with different specifications of the wire, an important step in confirming that the crimping is qualified is the tension test. According to the difference in wire diameter, different reference tension standards are used for testing. For wire samples of the same diameter crimped with the same terminals, a special tension machine is used for testing, and the cable can be crimped if it meets the tension standard.

Fifth, after selecting the cable specification material, the insulation test is performed after the production process. After the high-voltage wire completes the harness production, the premise of confirming whether the produced harness can be used for the entire vehicle production is to carry out an insulation test. This not only checks whether the insulation is good but also determines whether the selected cable used for design will have a high-voltage breakdown, thereby ultimately verifying whether the product produced is qualified.

In addition to the above five points, attention should also be paid to the fact that all high-voltage harness components should meet the load and voltage requirements.

Contact us:

yanjing@1vtruck.com +(86)13921093681

duanqianyun@1vtruck.com +(86)13060058315

liyan@1vtruck.com +(86)18200390258

Post time: Jul-26-2023