In this rapidly changing era of technological advancements, people have a strong pursuit of a high-quality life. Similarly, Yiwei Automotive has stringent requirements for the quality of its new products. From the product planning stage to the production preparation stage, every individual at Yiwei is attentive, meticulous, and dedicated to every aspect, investing their enthusiasm into each new product to ensure that it meets the market requirements and satisfies the various needs of customers. Now, let me introduce the quality management process of Yiwei’s new energy vehicle development. Product Planning Stage: Yiwei analyzes the market situation, potential user demands, interpretation of relevant policies, and relevant technologies and current status to determine new product projects. After the project is initiated, the size and layout of the development vehicle are clearly defined, and an objective analysis and evaluation of competing models are conducted.

Quality is involved in activities such as reviewing the options for electric powertrain, platform selection, feasibility of control systems, and selection of drive motors to ensure that the vehicle design meets the potential user demands. Concept Design Stage: Various proposals for the new project are put forward during the initial design stage, and quality targets are set in accordance with relevant national standards, such as safety performance, power performance, fuel efficiency, maximum gradient, etc. By systematically defining various quality indicators of the vehicle, the optimal performance status of the entire vehicle can be achieved.

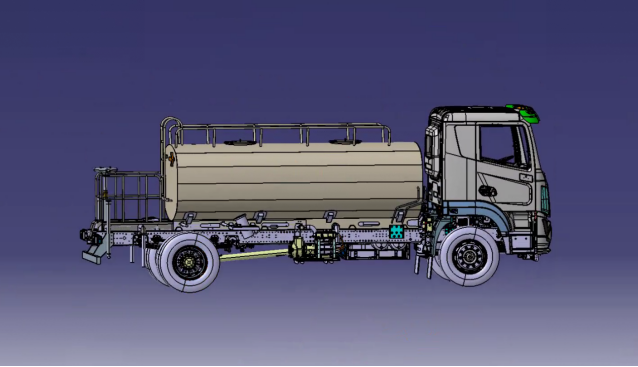

Engineering Design Stage: During this stage, Yiwei organizes senior experts and the technical and quality teams to analyze the overall performance and layout feasibility of the new project. Measurement and regulatory objectives are implemented to ensure the rationality of the overall design of new energy vehicles, guarantee the required performance and functionality of the products, and meet the objectives set during the concept design stage.

Prototype Testing Stage: Quality summarizes the issues encountered during the production of the entire prototype vehicle, promotes problem rectification, and optimizes related production process designs. Prototype vehicles undergo site reliability testing, high-level testing, and road reliability testing to verify the overall reliability, feasibility, and practicality of the vehicles.

Production Preparation Stage: After the project undergoes preliminary reviews and reliability verification, it enters the small-scale production stage. During this stage, small-scale production is carried out to verify the suitability and feasibility of the production process and assembly line, ensuring consistency when the vehicles are rolled off the production line. Yiwei adheres to the philosophy of “unity of heart and mind, striving for excellence” and sincerely manufactures products that customers can trust. Let us join hands together to create a better home!

Chengdu Yiwei New Energy Automobile Co., Ltd is a high-tech enterprise focusing on electric chassis development, vehicle control, electric motor, motor controller, battery pack, and intelligent network information technology of EV.

Contact us: yanjing@1vtruck.com +(86)13921093681 duanqianyun@1vtruck.com +(86)13060058315 liyan@1vtruck.com +(86)18200390258

Post time: Oct-23-2023